Heya Mould is a professional China Commodity mould Manufacturers and Commodity Mould Suppliers. It was established in 2013 With the professional solutions, strict and good quality control, competitive price, fast response, Heya get good feedback from our global clients. The molds we can manufacture for you are: Commodity Mould(Chair Mould,Table Mould,Stool Mould, Basket Mould,Bucket Mould,Dustbin Mould),Thinwall container mould, Spoon & Fork & Knife mould, Industrial Supplies Molds(Plastic Crate Mould,Pallet Mould,Flower Pots Mould),Household Appliance Mold .

We have rich experience and expertise in gas assist mold and moulding, overmolded mold and moulding, thin wall products mold and moulding,Basket mould,thread mold and moulding, stack mold and moulding

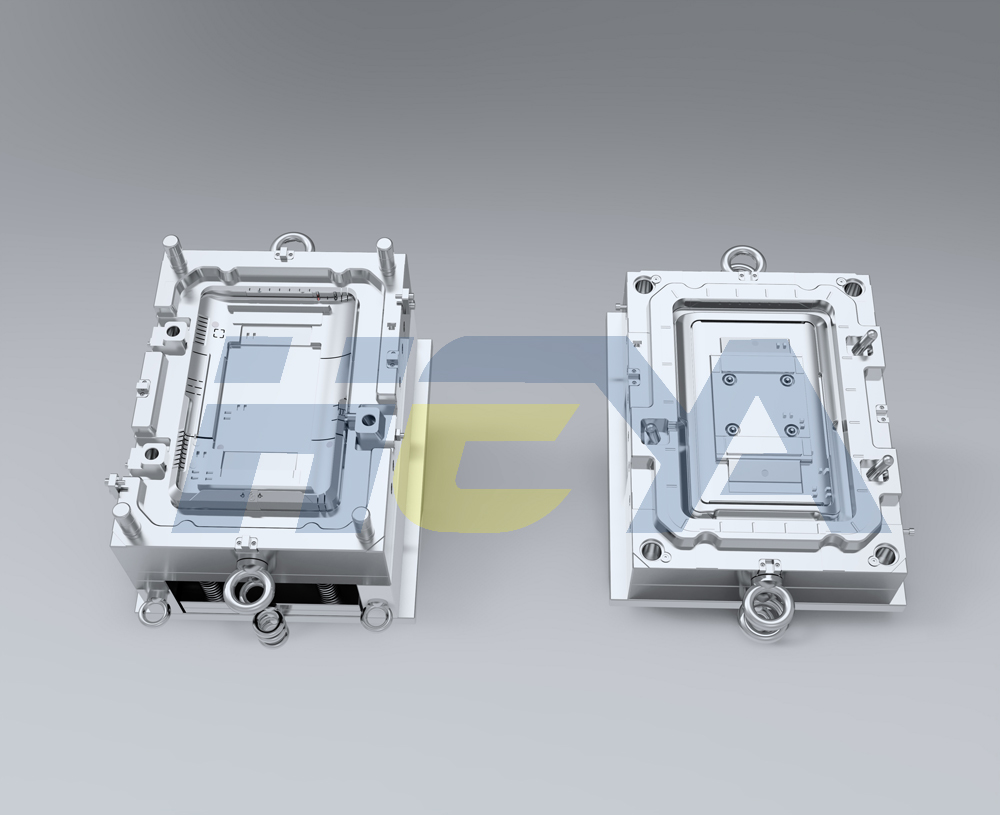

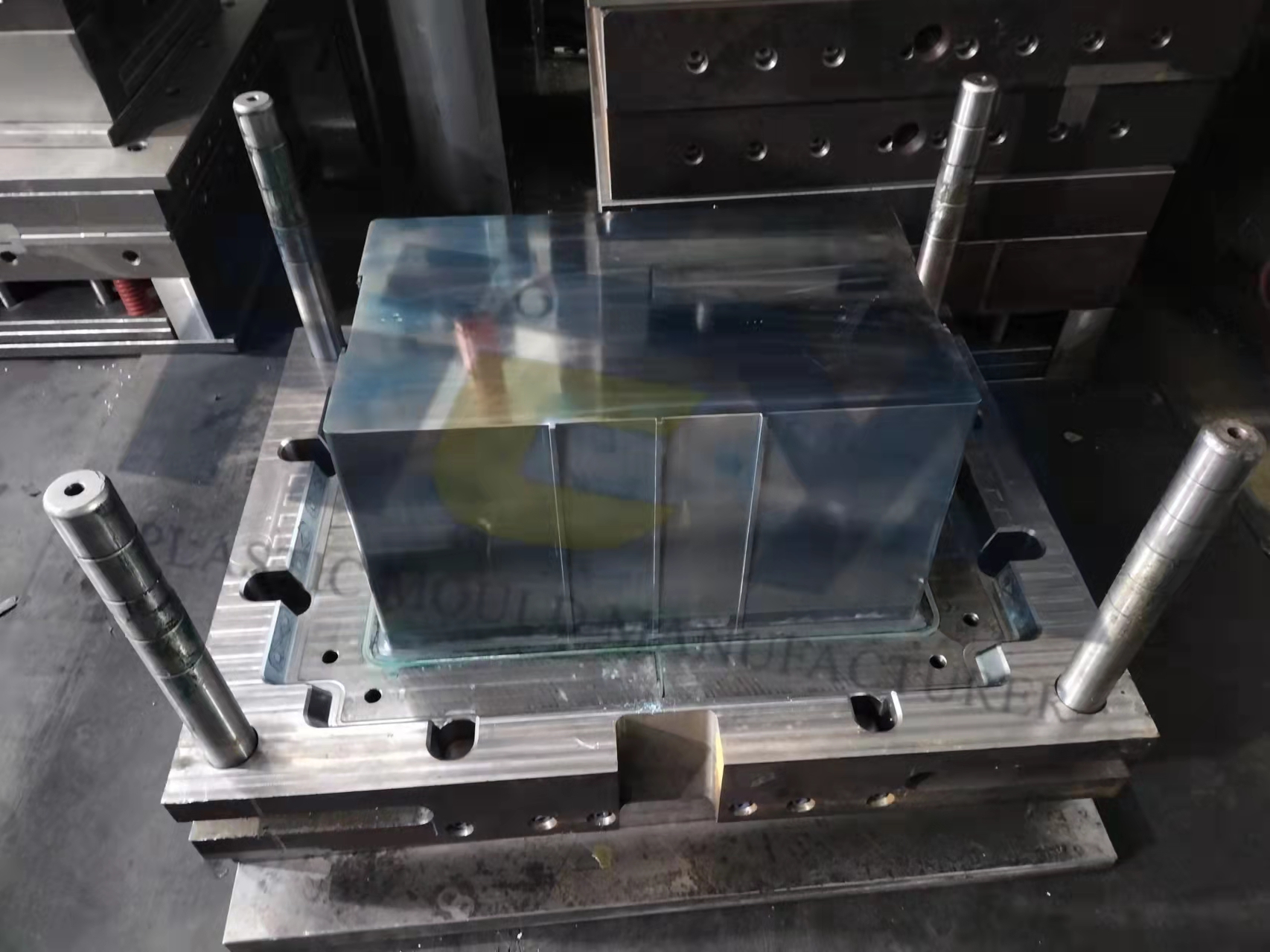

HEYE mould is professional in making various of size plastic container mould. HEYE can design plastic container moulds according to customer requirements, and also has a variety of plastic container product design drawings for cust...

Spoon/fork/knife molds can be divided into different categories according to their materials, shapes, patterns, usage: According to different product materials, it can be divided into PP spoon mold, PS spoon mold

Heya mold have been manufacturing different style of Industry and agriculture mould for customers around world. Our Industry and agriculture mould including Crate mould, Pallet mould, Flower pots mould

Heya has the home appliance mould project teams. Heya supply one set of home appliance mould solution according to customer’s idea; then form one complete mature set of mould solution,a variety of high-quality mould steels

Heya Mould is the leading plastic chair mould manufacturer in the China, we has developed more than 100 sets various chair moulds during these years, such like rattan design outdoor chair mould, beach chair mould,

Compared with normal plastic chair, rattan chairs are more high-end, it's more suitable for courtyards and high-end cafes etc. Rattan chair mould tooling cost are also more expensive than normal chair ...

Outdoor Chair Injection Molds belongs to the Chair Mould under the Household Molds. According to the different product styles, the Chair Mould can be divided into traditional style and personalized sty...

Heya mould use large CNC milling center for making the beach chair mould milling,deep hole drilling for the long size of plastic molding cooling water system.Therefore, the beach chair product you gain...

Heya is a full service molding that a 8500 square foot facility housing our molding department in-housing mold making , quality control. Warehousing secondary operations and offices , If we find a clie...

If you have any custom Stackable plastic chair moulds that is looking for a mold manufacturer to make this for you, you are welcome to send us your requirement for quotation,We have over 12 years of ex...

Heya Mould is your best choice for folding chair mould supplierChina. We can offer you 2D and 3D design of folding chair mould, we can make a modification with your design according to your special req...

The 28th HEYA MOULD Attend exhibitions Plastpol 2024 International Plastics and Rubber Fair will welcome its visitors again after a year at the exhibition centre in Kielce, Poland.We cordially invite y...

read more

A HEYA team consists of extremely skilled professionals who have been actively involved in the plastic mold industry for the past ten years. Coupled with this experience, the company is well-positioned...

read more

We have rich experience and expertise in gas assist mold and moulding, overmolded mold and moulding, thin wall products mold and moulding,Basket mould,thread mold and moulding, stack mold and moulding,...

read more

1、Types of Turnover BoxesThe turnover box is mainly used to transport various products, so it is also called the logistics box.According to the different products transported, there are mainly the fol...

read more