The sprue is the first channel that molten material is exposed as it goes from the barrer and nozzle into the mold and begins directing the molten plastic material toward the mold cavity. The corresponding part is referred to as the sprue bushing. The sprue bushing is designed as a"shelf item", available through a number of manufacturers by no means standard to every molding process

The typical design of a sprue starts with a smaller-diameter opening (but must larger than the diameter of nozzle)at the nozzle-sprue bushing interface, tapering to a larger-diameter opening as it

The depth and diameter are two important factors in design.

The depth and radius of the sprue enters the runner system

are critical so that proper sealing can take place between the nozzle of injection machine and the sprue bushing to avoid leakage of molten polymer. For cold runner mold, the overall diameter of

sprue is kept small to reduce the cooling needed, thus keeping the overall molding cycle time minimal and less waste. For hot runner systems, larger-diameter tapered sprue can be used, since in

this case the material remains molten inside the runner until it enters the cavity.

The opening of the sprue at the nozzle interface typically comes in a variety of diameters

Standard sizes range from 0. 125 in(3.2 mm) to approximately 0.500 in(12.7 mm).A rule of thumb

for the opening at the sprue-runner interface is that the diameter of the sprue matches the diameter

of the runner. It is recommended that the entry of the sprue bushing not be less than 0.125 in(3.2

mm)or larger than 0.500 in(12.7 mm). The diameter of the nozzle not only depends on the volume

of injection machine, but should be smaller than the opening of the sprue bushing diameter.

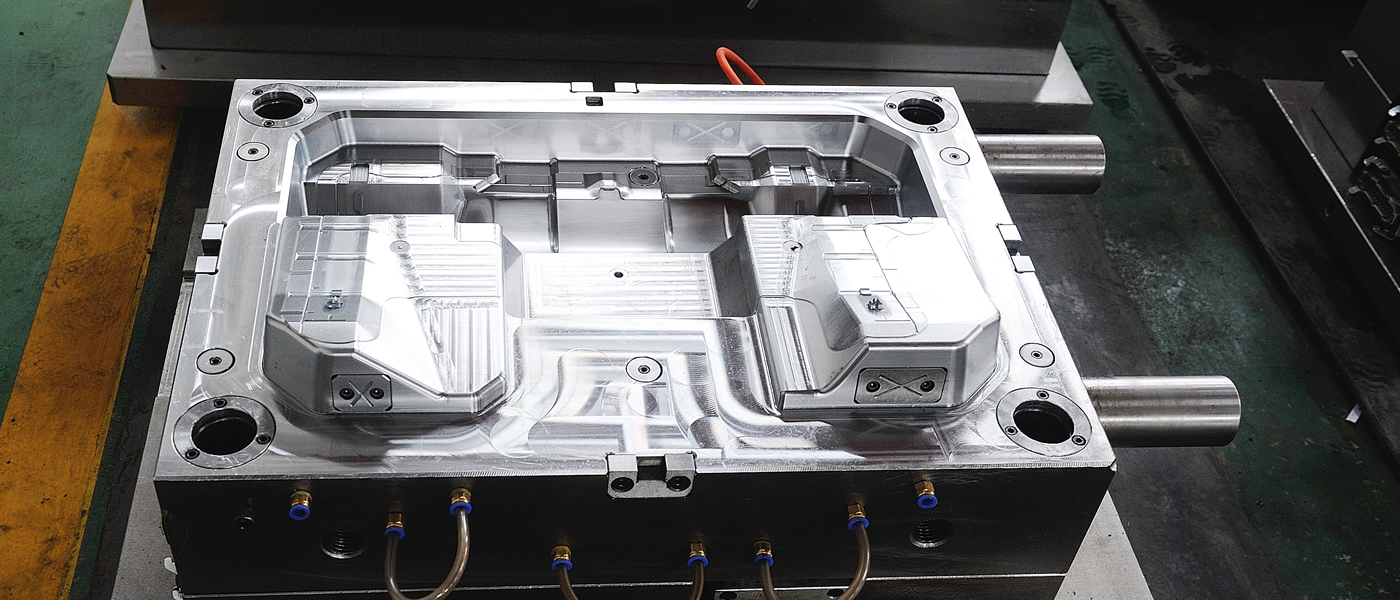

Heya focuses on manufacturing all kinds of plastic moulds, like household molds, kitchenware molds, home appliance moulds, industry and agriculture molds, crate mould, chair moulds, injection pallet molds and so on, stool molds, table moulds and so on. If you have new mould projects, welcome to contact us!