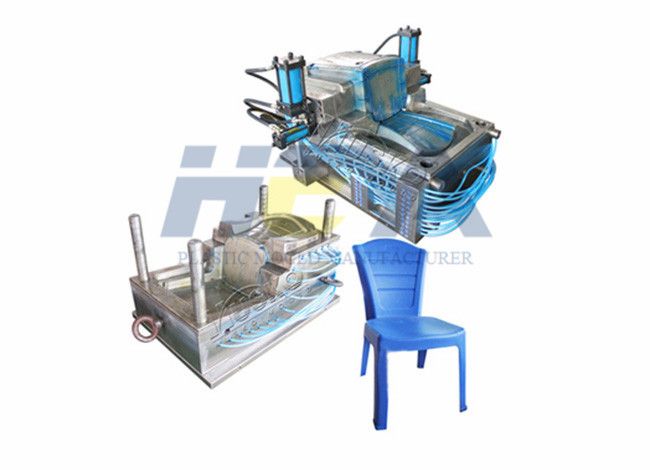

ventilated plastic chair mould

Chair Mould1. PC ghost chair mould, gas assisted chair mould, beach chair mould, leisure chair mould, rattan chair mould etc.2. Every year produce more than 200sets of chairs.3. Interchangeable insert block different versions of chair backrest & back rest inserts can be easily replaced on the machine.4. Cycle time 35 to 40 seconds for high speed running cycle.5. Top quality Chinese chair moulds manufacturer.

Product Description

1. PC ghost chair mould, gas assisted chair mould, beach chair mould, leisure chair mould, rattan chair mould etc.

2. Every year produce more than 200sets of chairs.

3. Interchangeable insert block different versions of chair backrest & back rest inserts can be easily replaced on the machine.

4. Cycle time 35 to 40 seconds for high speed running cycle.

5. Top quality Chinese chair moulds manufacturer.

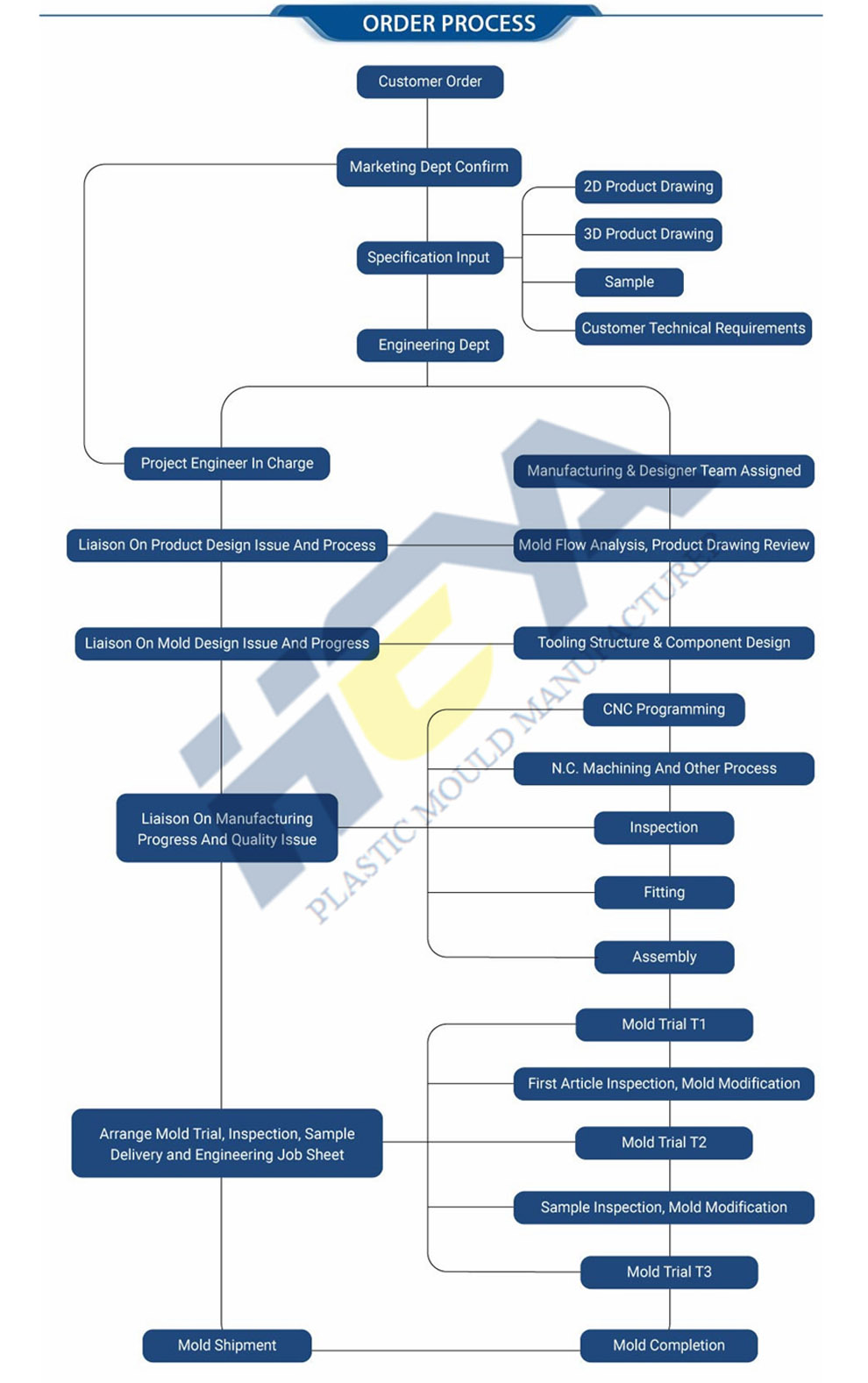

| 1. R&D:We suport customer R&D. Make the files or inprove the design if you needed. |

| 2. Quotation Making:Mould quotation will be finished in 1 day according to information we get. |

| 3. Negotation:The quality, price, material,delivert time, payment item ect. |

| 4. Mould Design:3-5days for mould and product 3D/2D drawing design. |

| 5. Mould:According to customers'request to build the mould before make the mould. We send mould design to customer approval first. Mould will be usually finished in 40-50 days. |

| 6.Mould Testing:When moulds are finished, we test the moulds to check it satified consumers' needs.And we will send samples for consumers'reference. |

| 7.Sampleshoot:If the first sample come out is not satisfied customer. We modify the mould and until meet customers' satisfaction. |

| 8. Delivery:Delivery goods by sea or by air, according customers requirement. |

| Name: Factory direct produce quality plastic shelf injection mould |

| Mould material:NKA80,S136, 2316,2736,H13,718H,P20,45# ect. |

| Product Material:PP,PE,PC,PA,PS,PU,PVC,PMMA,ABS ect. |

| Cavity No.:Single or multi. |

| System of runner:Hot runner,cold runner,pin-point gate,hydro-cylinder etc. |

| Time pf mould production:45 days -60 days. |

| Guaranteed Number of Cycles:300,000-3,000,000 |

| Mould design software:UG,IGS,STP |

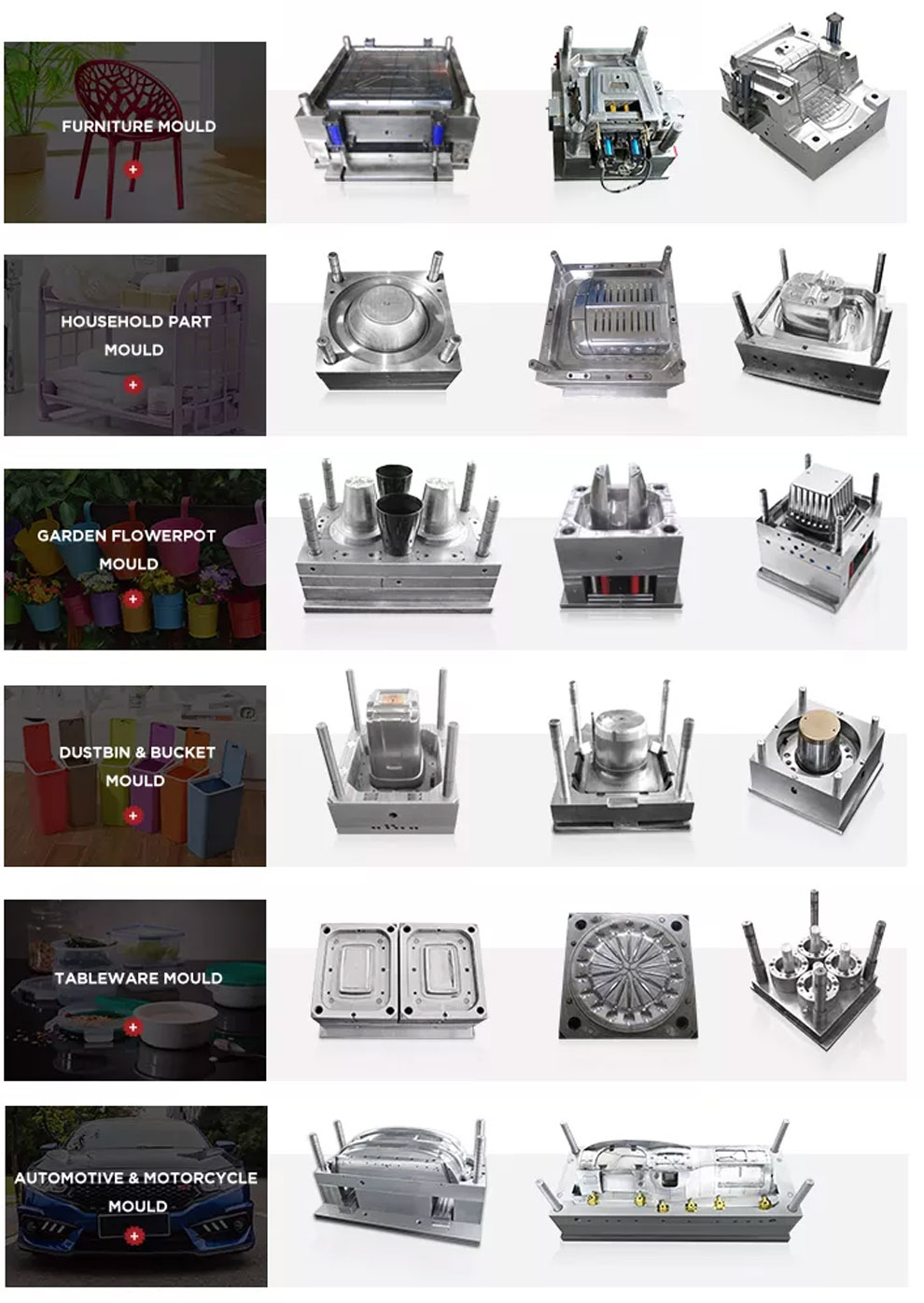

molds we make

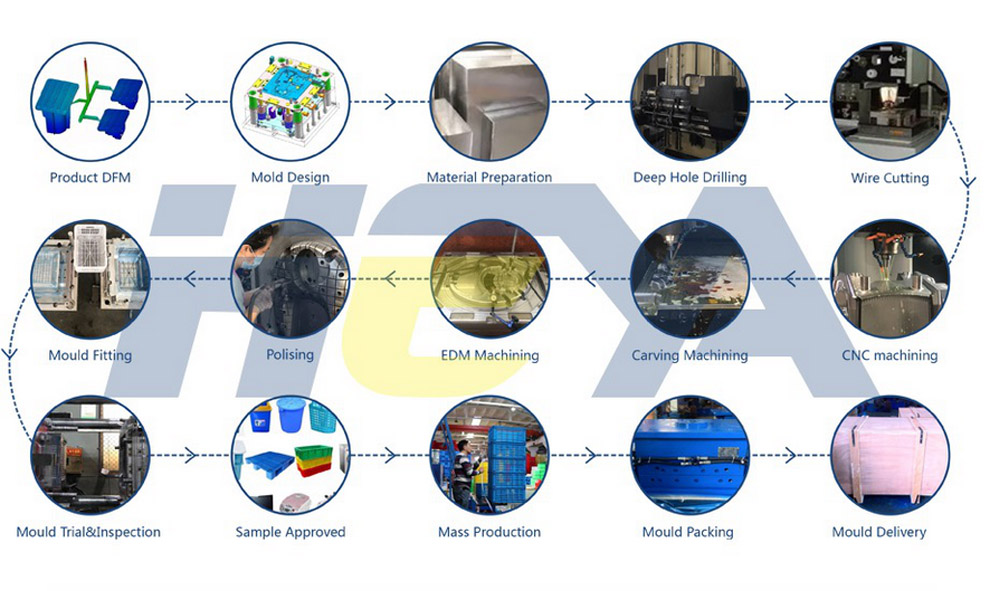

MOULD MAKING

1.Samples/Drawing &Requirement from you

2.Mould design:we will Communicate and Exchange the opinion with you after you place order.

3.Material Purchase:Steel cutting and Mould base tooling.

4.Assembling.

5.Inspection of mould : following and controlling the tooling processing.

6.Mould testing:We will inform you the date.Than will send the sample's inspection report&injection parameters with the sample to you!

7.Your instruction &confirmation for shipment.

8.Ready made mould before packing.

Frequently ask question

A:We will submit the quotation in 24 hours if getting detailed information during working days. In order to quote for you earlier, please provide us the following information together with your inquiry:

1)3D Step of Files and 2D Drawings

2)Material requirement

3)Surface treatment

4) Quantity (per order/per month/annual)

5) Any special demands or requirements, such as packing, labels, delivery, etc

A:1). Materials inspection by IQC;

2). During processing, our IPQC will check the injection molded parts every

3). hours, ensure no any rejects;

4).FQC will check the products before sending to the warehouses

5).100% inspected by QC before shipping out.

A:1). For moulds, we will be coated one-layer anti-rust oil first, and then also will be covered thin films on the mould, finally pack into fumigation wooden case.

2). And as to products, we will pack into standard export cartons or as per customer's request to pack.

Reviews

Related Mould

Ratten Plastic Chair Mould

Ratten Plastic Chair Mould belongs to the Chair Mould under the Ratten Plastic Ch...

Plastic Chair Mould

Plastic Chair Mould refers to the mold used to produce Chair Mould with injection...

Outdoor Chair Injection Molds

Outdoor Chair Injection Molds belongs to the Chair Mould under the Outdoor Chair ...